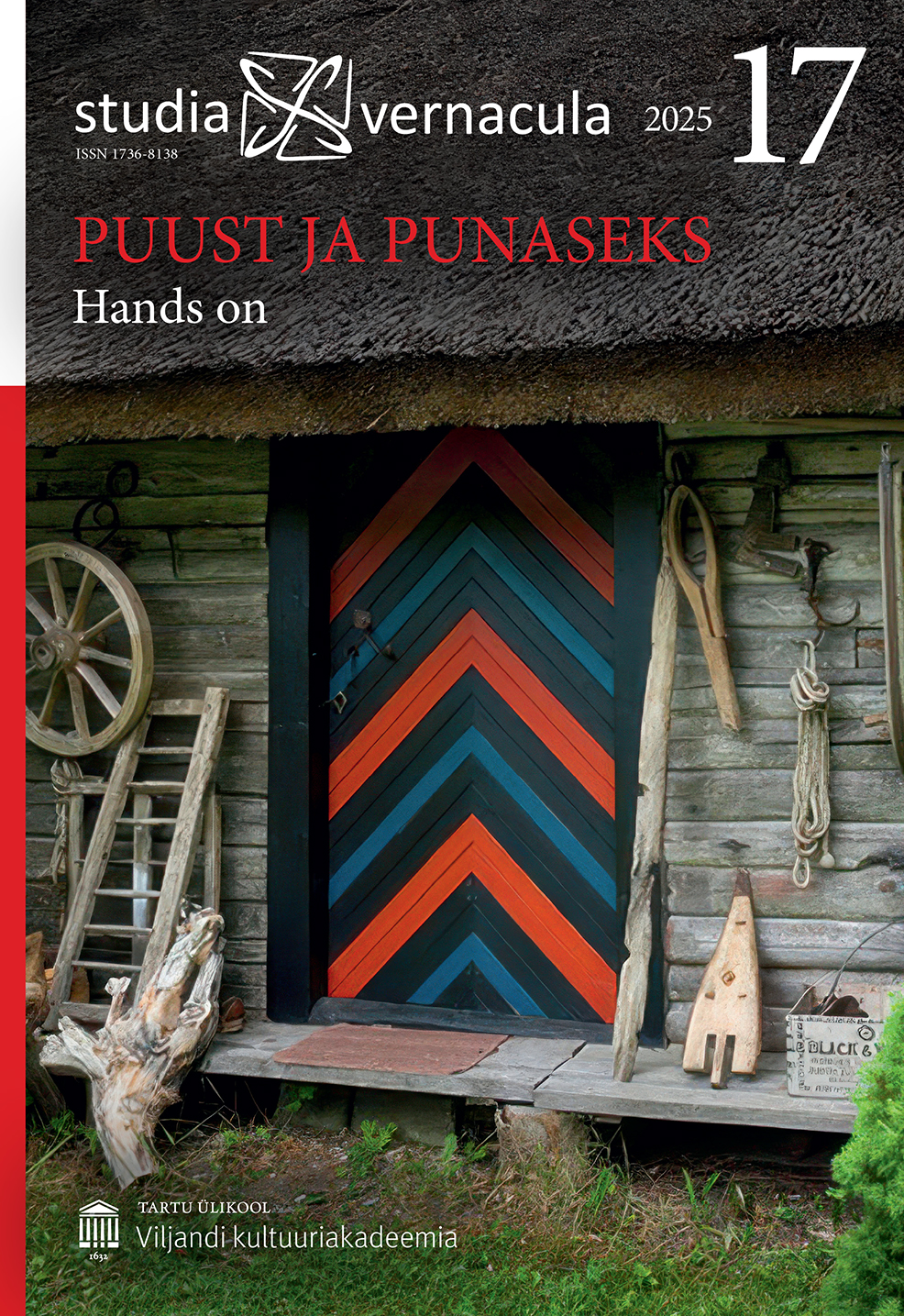

Maakivilaudast elumajaks: Lepiku talu näitel

DOI:

https://doi.org/10.12697/sv.2025.17.222-242Abstract

The article offers an autoethnographic overview of my first large-scale renovation project, a ruined fieldstone barn building that needed to be reconstructed into a private home within four years. The restoration and renovation of the building required a long-term commitment to laying and jointing fieldstone. The article uses autoethnography to reflect the years long working process. In the course of the project traditional techniques were combined with modern tools and technologies.

Today fieldstone, when used as a sustainable recyclable building material, does not constitute the most economical choice, considering the maintenance costs and use of time as a resource for construction. In addition, we have to consider carefully whether such a building is suitable for permanent living, as in the winter the walls might sweat and frost might cover the interior, or mould generated by moisture might be your cohabitant.

Experience shows that the use of ground source heating in a stone building is an effective and practical solution. The heat rising from the subfloor spreads evenly, warming the stone walls as autumn arrives and preventing them from cooling down for winter. Ground source heating is particularly suitable for stone houses as walls and floors act as natural heat storage units. The system uses the natural heat stored in the ground, which has relatively stable temperatures throughout the year. In addition, the even heat keeps the temperature of the stone walls above zero in the winter, which in turn reduces the risk of frost damage and condensation. The efficiency of ground source heating can be further improved by combining it with a modern ventilation system that helps maintain heat and ensure air circulation and moisture balance.

Another modern solution to be used is thermal plaster. Since the building is covered with fieldstones both inside and outside, it has no additional insulation whatsoever. Winter observations show that frost occurred over the entire length of the outside wall, while in the inner corners it occurred approximately 70 cm above floor level. The heat loss problems result from the thermal conductivity of the stone and the effects of thermal bridges. The solution turned out to be thermal plaster, which is four times lighter in weight compared to classic plasters and has low thermal conductivity, so it can be used on mineral substrates. All corners of the house and the surfaces behind cupboards were covered with a layer of thermal plaster to improve thermal insulation and reduce the impact of thermal bridges. As a result of the process, I can argue that it is possible to live in a traditiona fieldstone building and that living conditions can be improved using modern solutions.

Keywords: fieldstone, fieldstone building, jointing of stones